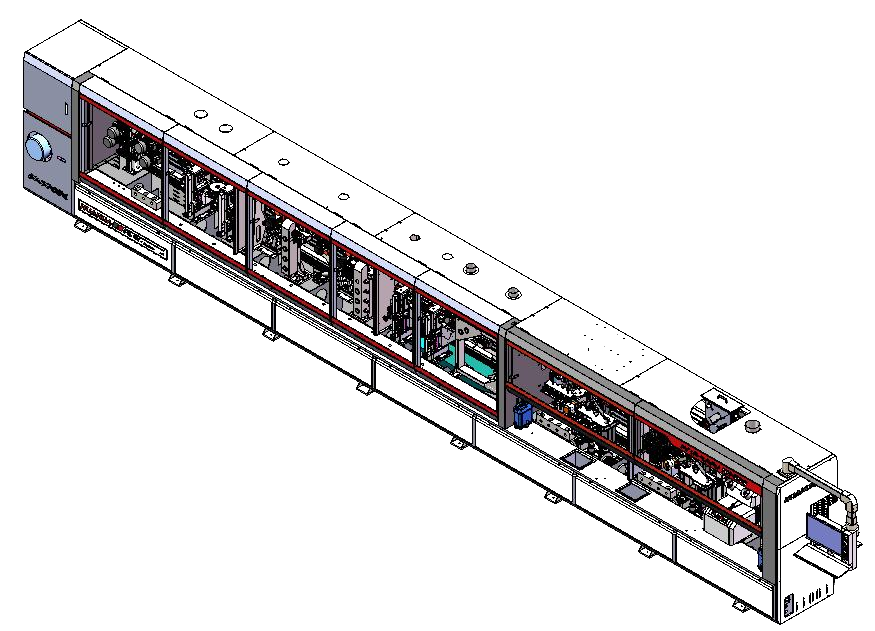

HUAHUA CNC continues to lead the woodworking industry with its innovative HH-796RK-SERVO edge banding machine. Designed for precision and efficiency, this machine features advanced capabilities that enhance the edge banding process, making it an essential tool for woodworking professionals.

Floating Flat Scraping for Superior Results

One of the key features of the HH-796RK-SERVO is its floating flat scraping mechanism. This pneumatic scraping technology effectively removes any remaining glue extruded from the joints of the upper and lower planes of the edge banding attached to the panel. By ensuring that excess glue is eliminated, this feature helps achieve a cleaner finish and enhances the overall quality of the product. The floating flat scraping system is designed to work seamlessly, allowing for smooth operation and consistent results, making it a standout in the category of edge banders.

Reduced Downtime with Efficient Buffing

Another significant advantage of the HH-796RK-SERVO edge banding machine is its ability to minimize the likelihood of glue sticking to the buffing wheel. This feature not only maintains the efficiency of the polishing process but also reduces the frequency of polishing wheel replacements. Consequently, businesses can experience less downtime and lower maintenance costs, further enhancing productivity. The efficient design of this edge bander allows operators to focus on production without the interruptions commonly associated with glue buildup.

Conclusion

In conclusion, HUAHUA CNC’s HH-796RK-SERVO edge banders offer innovative features like floating flat scraping and efficient buffing, providing woodworking professionals with the tools they need to achieve high-quality finishes. By investing in this advanced edge bander, businesses can improve their edge banding processes, reduce maintenance costs, and ensure exceptional craftsmanship in their products. HUAHUA CNC remains committed to delivering solutions that elevate the woodworking industry.