Liquid Silicone Rubber (LSR) moulding is gaining recognition in various industries due to its remarkable properties, including high precision, heat resistance, and chemical resilience. Henry Precision, a player in the field, integrates cutting-edge technology to enhance LSR moulding, providing manufacturers with reliable, high-quality components. This article explores the core advantages of LSR moulding and highlights how Henry Precision’s expertise ensures superior results.

High-Quality Parts with High Precision in LSR Moulding

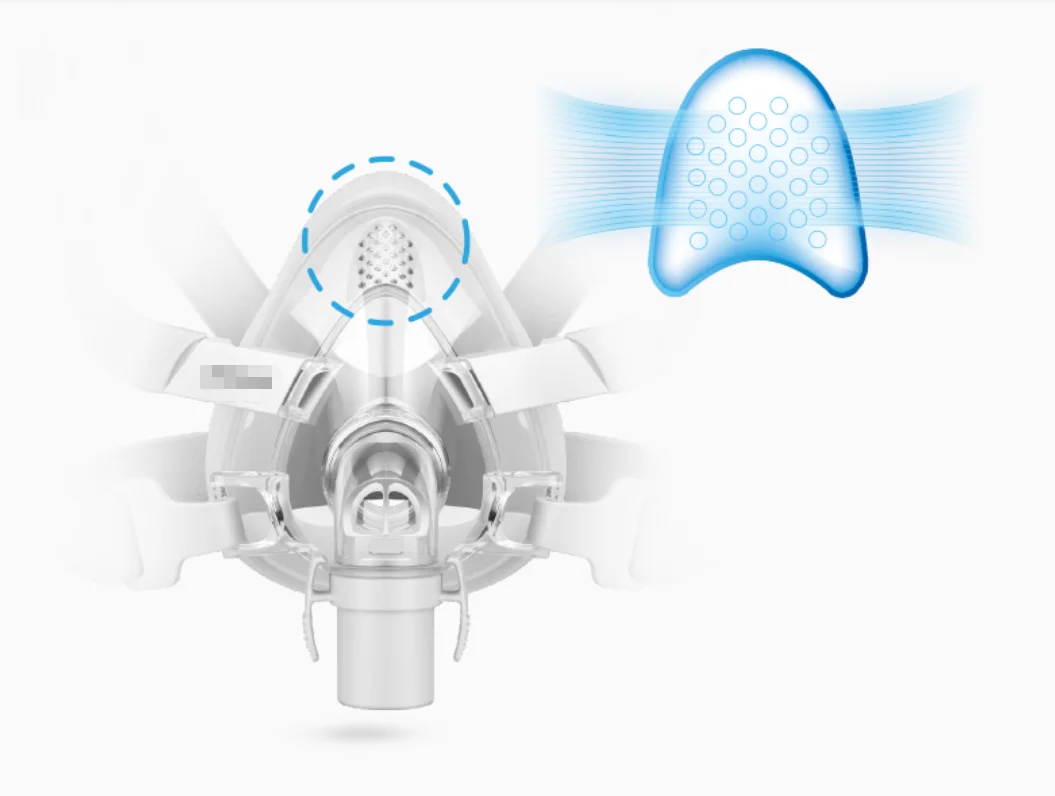

LSR moulding is known for its ability to produce parts with extremely tight tolerances, up to ±0.02mm, ensuring each product meets exact specifications. Henry Precision has perfected this aspect of the technology, ensuring that components are consistently manufactured to the highest standards. Whether producing intricate medical devices or durable automotive parts, the precision offered by LSR moulding guarantees reliable performance.

Heat and Chemical Resistance of LSR Components

One of the standout features of Liquid Silicone Rubber Moulding is its exceptional resistance to both heat and chemicals. LSR can withstand temperatures ranging from -50°C to 200°C, making it ideal for use in extreme conditions. Furthermore, its resistance to acids, alkalis, and other harsh chemicals ensures the longevity of parts exposed to such environments. Henry Precision takes advantage of these properties, ensuring that components remain durable and effective even in the most challenging conditions.

Biocompatibility and Automation in LSR Moulding

LSR’s biocompatibility makes it a preferred choice for medical and healthcare applications, as it complies with FDA and ISO13485 standards. Whether used in implants or other critical medical devices, LSR ensures safety and reliability. Additionally, Henry Precision supports fully automated LSR moulding processes, allowing for high production efficiency and consistent quality across large volumes of parts. Automation reduces human error and accelerates production timelines, making it a valuable solution for industries demanding high throughput.

Conclusion

LSR moulding continues to play a crucial role in manufacturing high-performance parts for industries ranging from healthcare to automotive. With Henry Precision’s advanced technology, the process is not only more efficient but also yields consistently high-quality results. As the demand for precision and reliability increases, Henry Precision remains at the forefront of LSR moulding innovation, helping to drive progress across various sectors.